Contact us for help with your samples

Overview of the LECO VX Series

The LECO VX Series Metallurgical Microscopes are advanced microscopy solutions for materials labs requiring high-resolution imaging and reliable metallographic analysis. Designed for precision, repeatability, and ease of use, the VX Series supports laboratories in industries ranging from automotive and aerospace to academic research and quality assurance.

Whether you’re analyzing microstructures, assessing welds, or conducting failure investigations, the VX Series provides high-resolution imaging and robust performance that professionals rely on. With integrated digital imaging systems and compatibility with LECO’s suite of analytical tools, the VX3, VX4, and VX5 offer scalable solutions for labs of all sizes.

The Ideal Microscopes for Metallography

LECO metallographic microscopes assist laboratory technicians in examining the intricate microstructures of metals and alloys. This important step in the metallographic process allows researchers to analyze grain structure and to better identify possible defects. The level of detail provided by metallographic microscopes can assist quality assurance, failure analysis, and material inspections across a wide variety of industries.

Shown with Pax-Cam and Schott ring-light, sold separately.

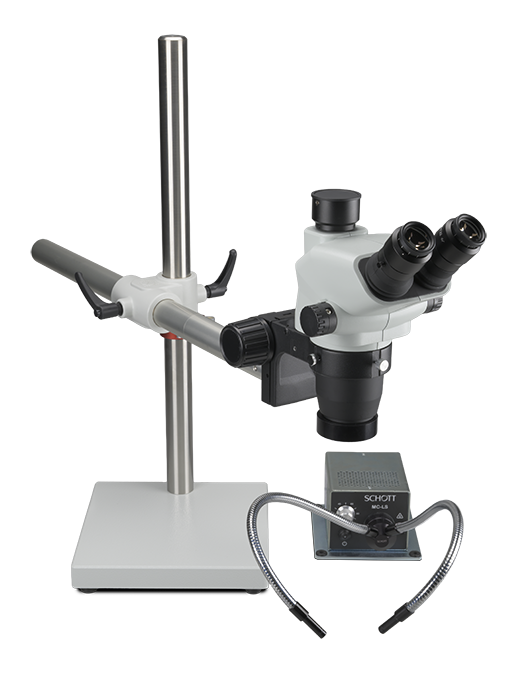

Shown on Boom Stand with Schott-MC-LS-Light, sold separately.

VX3 Stereo Microscope

Engineered for precision, versatility, and durability, the LECO VX3 metallurgical microscope fulfills the rigorous demands of advanced metallographic analysis. Built to deliver exceptional imaging clarity and reliability, the VX3 supports a wide range of metallurgical and inspection applications, including weld analysis, failure analysis, and in-process inspection for fasteners. With its ergonomic design and high-resolution optics, the VX3 is ideal for both industrial quality control and academic research settings. It features click-stop magnification zoom and a built-in light splitter for streamlined, repeatable workflows.

Key Features of VX3

-

- Repeatable Measurements – Click stops on magnification zoom ensures repeatable magnification

- Built-in Light Splitter – Light is permanently drawn to both the camera and eyepieces simultaneously

- Camera Adapter Versatility – 0.35X, 0.5X, 0.65X, and 1.0X adapter availability

- Flexibility and Durability – 25 in flexible boom stand with horizontal slider dead stop

VX4

VX4 Compact Inverted Microscope

The LECO VX4 is a compact and practical microscopy solution for any metallurgical or educational laboratory. This microscope comes equipped with a vibrant LED polarized light source that is perfect for inspecting mounted and unmounted samples. Engineered for enhanced optical performance and ease of use, the VX4 features state-of-the-art imaging systems and automated functionality to support complex material investigations. Whether conducting microstructural analysis for grain size, pearlite/ferrite, nodularity, dendrite arm spacing, or advanced failure analysis, the VX4 delivers unparalleled detail and precision. Its compatibility with LECO’s analytical software further enhances workflow efficiency, data management, and reporting. The VX4 is the optimal choice for laboratories demanding cutting-edge technology in metallography and material characterization.

Key Features of VX4

- Variable LED light source with built-in lever condenser with field and aperture diaphragms

- Trinocular head with 10X/22 mm adjustable focusing eyepieces

- Revolving nosepiece holds up to five objectives

- 5X, 10X, 20X, and 50X included

- Optional 100X objective available

- Brightfield observation and 360-degree polarizer/analyzer

- Coaxial coarse and fine focus adjustment

- Ergonomic mechanical XY stage

Revolving nosepiece holds up to five objectives.

VX5

Shown with HD Camera/Monitor System, sold separately.

Revolving nosepiece holds up to five objectives.

Shown with PaxCam, sold separately.

Shown with PaxCam, sold separately.

Shown with HD Camera/Monitor System, sold separately.

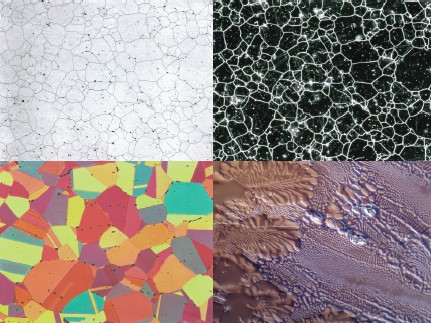

VX5 photo samples of material analysis.

VX5 Inverted Microscope

Built around advanced LWD M Infinity Plan Achromatic optics, the VX5 provides the image clarity essential for consistently distinguishing fine structural details. This optical foundation ensures you get the resolution and contrast needed for confident analysis, regardless of complexity.

Adaptable Observation for Complex Analysis

The VX5 supports Brightfield, Darkfield, Polarized Light and Differential Interference Contrast (DIC), providing you with the right method for each specimen’s unique characteristics

Efficiency Built into Daily Operation

The Smart ECO Illumination recognizes idle time and powers down automatically, a practical consideration for labs running multiple shifts

Optical Precision Where it Counts

LWD M Infinity Plan Achromatic optics deliver the resolution needed to distinguish fine structural details in your samples

Documentation that Supports your Findings

Integration with LECO’s PaxCam or HD Camera/Monitor systems lets you build visual records that back up your metallurgical conclusions

Key Features of VX5

- Infinity corrected optical system

- 12 V/100 W halogen illuminator with variable intensity and indicator; adjustable and centerable field and aperture diaphragms; ECO system turns illumination off when not in use

- Trinocular head, 45-degree inclined, interpupillary distance adjustment: 50-75 mm; image may be sent to either binocular head or camera/video port

- Revolving nosepiece holds up to five objectives

- 5X, 10X, 20X, and 50X BF/DF infinity corrected M Plan objectives come standard

- Optional 100X objective available

- Color filter slide with three filters (green, yellow, and clear daylight blue); fixed analyzer and polarizer are standard; optional 360-degree rotatable analyzer and optional DIC slider are available

- 240×250 mm integrated three-layer mechanical stage; movement range 50×50 mm; X-Y Vernier scales; low position right-handed stage controls; 12 mm and 25 mm teardrop stage plate inserts

- 100–240 V input; 12 V/5 A output power supply (CE, UL listed)