A chemistry-inspired look at romance, aroma, authenticity, and quality powered by LECO workflows.

Roses, wine, chocolates, perfume, makeup, cheese, bread—the Valentine’s table pictured below is full of sensory highlights. It’s also full of chemistry: complex aroma profiles, authenticity questions, and the occasional need to screen for unwanted compounds. With the right analytical workflows, these everyday items can reveal clear, actionable data.

Below is a Valentine’s table “menu” of real-world examples. Each item has been tested using LECO application workflows.

1. Chocolates & Chocolate Liqueurs—Why the Aroma is so Complex (And How to Measure It)

Chocolate is one of the most chemistry-rich treats on the table. Its aroma depends on cocoa origin and processing steps such as fermentation and roasting—all of which shape the volatile profile your tastebuds perceive as “nutty,” “roasted,” “fruity,” “floral,” or “spicy.”

The Analytical Challenge: Coelution

Cocoa’s volatile fraction can span hundreds of compounds across many chemical classes and a wide concentration range. That complexity increases the likelihood of coelution in one-dimensional GC, where important contributors may be hidden. The goal is not simply more peaks, but better separation and confident identification of the compounds that drive sensory perception.

A LECO Workflow for Cocoa and Chocolate Using GCxGC

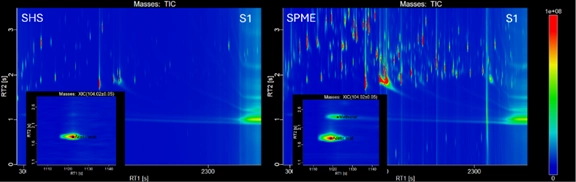

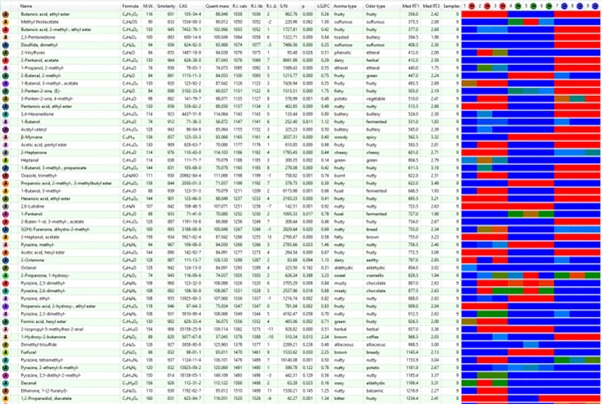

In the newly released cocoa/chocolate application note, cocoa liqueur samples from different geographic origins are characterized using comprehensive two-dimensional gas chromatography coupled with time-of-flight mass spectrometry (GCxGC-TOFMS). Two sampling approaches are compared—static headspace (SHS) and headspace solid phase microextraction (HS-SPME)—to evaluate extraction efficiency and the resulting volatile fingerprints.

The workflow combines HS-SPME with GC×GC-TOFMS to separate and detect cocoa volatiles, then uses LECO’s advanced software system, ChromaTOF Sync 2D, for data processing and alignment—enabling streamlined comparison across multiple samples (alignment, library searching, and multivariate/statistical comparison).

Instruments and Tools Used for Success

- Pegasus BTX 4D (GCxGC-TOFMS platform)

- GCxGC with QuadJet thermal modulation

- ChromaTOF Sync 2D for processing and comparison

With a richer, better-separated volatile fingerprint, you can differentiate origins or lots, track processing impacts, and build comparative profiles that support research and development (R&D) and quality control (QC) whether you’re evaluating chocolate, cocoa ingredients, or chocolate-flavoured liqueurs.

Read the App Note: Comparing Cocoa with Pegasus BTX 4D & Sync 2D | LECO

LECO Brings More to the Table

While chocolate is no doubt typically the star of the show, our Valentine’s table also features some common Valentine’s gifts and items centered around the holiday. Valentine’s Day is all about the senses—the aroma of freshly cut roses, the first sip of wine, the richness of chocolate, and the familiar signature of a favourite fragrance. But behind every “romantic” moment is a chemical fingerprint: volatile compounds that define aroma and flavour, trace contaminants that can spoil quality, and compositional patterns that help confirm authenticity and consistency.

That’s why this Valentine’s table makes such a fun (and surprisingly real) analytical showcase. Using LECO workflows, laboratories can profile aromas, detect trace off-notes, verify authenticity, and support quality and compliance across food, beverages, and consumer products. Each example below links to a relevant application note, so you can dive deeper into the methods and results.

2. Freshly Cut Roses—Aroma Profiling

Capture a floral volatile fingerprint for nontargeted screening and comparative profiling (e.g., variety, freshness, storage, or processing impacts).

Explore our Aroma and Flavor Resource Hub: Aroma Flavor Fragrance – LECO Corporation

3. Wine & Cork—Cork Taint Screening

Detect cork taint markers—such as TCA—at trace levels using HS-SPME + GC-TOFMS, helping protect sensory quality and reduce costly product complaints.

Read the App Note: Quantifying Cork Taint in Wine Using GC-TOFMS | Pegasus BT

4. Perfume—Authenticity and Compositional Profiling (Brand vs Imitation)

Differentiate brand vs. imitation by comparing full compositional profiles with GCxGC-TOFMS and visual pattern-comparison tools, supporting authenticity and brand protection.

Read the App Note: Differentiating Original-Brand and Imitation Perfumes – LECO Corporation

5. Makeup (Palette + Lipstick)—Fragrance Allergens & MOSH/MOAH Workflows

Identify fragrance allergens in cosmetics with GCxGC-TOFMS and support MOSH/MOAH screening approaches for lipstick matrices, helping labs meet safety and compliance expectations.

Read the App Note: GCxGC-TOFMS Workflow for Fragrance Allergen Compliance

Read the App Note: Trust Your Results: Mineral Oil Analysis Workflow

6. Whiskey—Aroma Profiling

Characterize and compare volatile signatures with SPME-GCxGC-TOFMS to support product differentiation, batch consistency, and maturation/aging studies.

Read the App Note: Whiskey Aroma Profiling with GC-TOFMS & Sync | LECO

7. Baked Camembert—Cheese Protein & Packaging MOSH/MOAH Risk

Combine cheese protein determination with MOSH/MOAH screening of packaging materials to assess potential mineral oil migration risk.

Read the App Note: Determining Nitrogen/Protein in Cheese with FP828

Read the App Note: Trust Your Results: Mineral Oil Analysis Workflow

8. Crusty Bread—Flour Quality and Consistency

Support flour quality specifications with combustion Nitrogen/protein analysis to monitor protein consistency and baking performance.

Read the App Note: Protein Determination in Flour Using the LECO FP828

As you can see, from the first pop of a cork to the last bite of chocolate, Valentine’s Day is full of chemistry worth exploring, and LECO has the right tools to do just that. Whether you’re profiling aroma, confirming authenticity, or screening for contaminants, our solutions provide labs with high-resolution separation, confident identifications, and actionable results across a wide range of industries and applications.

If you’d like to know more about these workflows, you can contact us directly and request more information.